Basic Info.

Model NO.

SAE4340/1.6511/EN24/40CrNiMo/SNCM439

Special Use

Mold Steel

Quality Assurance

100% UT passed

Heat Treatment

Annealing/Q+T

Technology

Hot Rolled/Forged

Payment term

TT/LC

Lead time

7days

Transport Package

Standard/Customized

Specification

standard/customized

Trademark

customized

Origin

China

HS Code

7228309000

Production Capacity

1000t/Month

Product Description

SAE4340/1.6511/EN24/SNCM439/alloy tool steel round bar

Similar Standards

Chemical Composition

Heat Treatment

Mechanical Properties

General Applications4340 alloy steel bar is used heavily in the aerospace industry due to its ultra-high strength. When heat treated it is known for its toughness while preserving good fatigue strength. For highly stressed parts it is excellent choice. It can be machined by all customary methods. This material is available in both vacuum melt (VM) and air melt (AM)

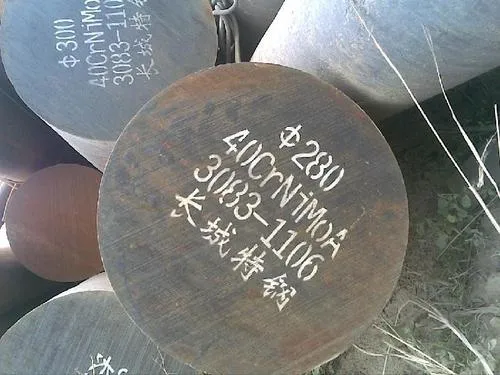

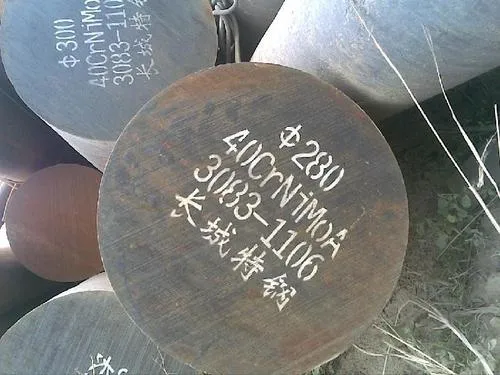

Product show:

Similar Standards

| Chinese | American | German | Japanese | British |

| GB | AISI | DIN | JIS | BS |

| 40CrNiMo | SAE4340 | 1.6511 | SNCM439 | EN24 |

| Carbon | 0.38-0.43 |

| Manganese | 0.60-0.80 |

| Phosphorus (max) | 0.035 |

| Sulfur (max) | 0.04 |

| Silicon | 0.15-0.35 |

| Nickel | 1.65-2.00 |

| Chromium | 0.70-0.90 |

| Molybdenum | 0.20-0.30 |

Heat Treatment

| Quenching | Tempering | ||||

| Heating Temperature/ºC | Cooling | Hardness/HRC | Heating Temperature/ºC | Cooling | Hardness/HRC |

| 820-840 | Oil | ≥53 | 450-650 | Air | 25-40 |

| Tensile strength (psi) | 105,000 - 115,000 |

| Yield strength (psi) | 75,000 - 85,000 |

| Elongation in 2" (%) | 20 - 30 |

| Reduction of area (%) | 35 - 45 |

| Brinell Hardness (BHN) | 210 - 240 |

General Applications

- Aircraft Landing Gear

- Power Transmission Gears

- Structural Use Applications

Typical Applications:

- High strength shafts

- Punches & dies

- Drill bushings

- Retaining rings

- Gears

4340 alloy steel bar is used heavily in the aerospace industry due to its ultra-high strength. When heat treated it is known for its toughness while preserving good fatigue strength. For highly stressed parts it is excellent choice. It can be machined by all customary methods. This material is available in both vacuum melt (VM) and air melt (AM)

EN24 is a very high strength steel alloy which is hardened and tempered before supplying and has nickel, chromium, molybdenum making it high tensile steel strength, with good ductility and wear resistance. With relatively good impact properties at low temperatures, EN24 is also suitable for a variety of elevated temperature applications. EN24 round bars have good internal strength and high external strength, which makes it highly wear resistant. EN24 steel round bars offer good combination of ductility, strength and wear resistance. En24 is a very high strength alloy engineering steel.

Features

EN24 Engineering Steel is easy to treat and temper and is supplied hardened and tempered. The alloy offers a good combination of strength, ductility and wear resistance. It is a very high strength alloy engineering steel.

Product show: