- Overview

- Product Description

- Product Parameters

- Company Profile

- Our Advantages

Basic Info.

Product Description

A-286 alloy is an age-hardenable iron-based superalloy for applications requiring long-term high strength from -195°C-538°C. If short-term high strength properties are acceptable, the alloy can be used between 704-816°C. Oxidation resistance is high for continuous service to 816°C and intermittent to 982°C.

Aqueous corrosion resistance of A-286 is comparable to 316/316L stainless grade.

Heat treatment according to AMS 5525 requires a solution anneal at 982°C air cool, age at 718°C for 16 hours and then air cool.

CHEMICAL ANALYSIS

| Cr | Ni | Mo | Co | Va | Al | Ti | B | C | Fe | Mn | Si | P | S | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | 13.5 | 24 | 1 | - | 0.1 | - | 1.9 | 0.003 | - | - | - | - | - | - |

| Max | 16 | 27 | 1.5 | 1 | 0.5 | 0.35 | 2.35 | 0.01 | 0.08 | Balance | 2 | 1 | 0.025 | 0.025 |

Applications

Super alloy A-286 is used in gas turbine forgings, fasteners, superchargers, cryogenic equipment, missile components, corrosive deep well hardware and jet engines.

| Mechanical & Physical Properties | 21°C | 93°C | 204°C | 427°C | 537.8°C | 649°C | 760°C |

|---|---|---|---|---|---|---|---|

| Coefficient of Thermal Expansion µm/mC | - | 16.6 | - | 17.3 | 17.6 | 17.8 | 18.5 |

| Modulus of Elasticity / x105 MPa | - | - | - | - | 1.65 | 1.52 | 1.59 |

| Ultimate Tensile Strength/ MPa | 999.7 | - | 986 | 951.5 | 903.2 | 710.2 | 441.3 |

| 0.2% Yield Strength/ MPa | 655 | - | 641.2 | 641.2 | 599.8 | 606.7 | 427.5 |

| Elongation % | 24 | - | 21 | 18 | 18 | 13 | 18 |

| Thermal Conductivity kcal/(hr.m.°C) | - | 11.9 | - | 14.6 | 19.3 | 21 | - |

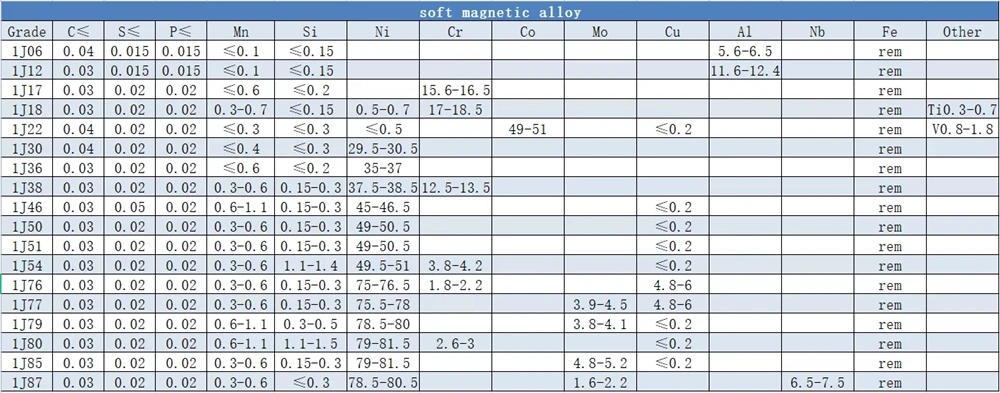

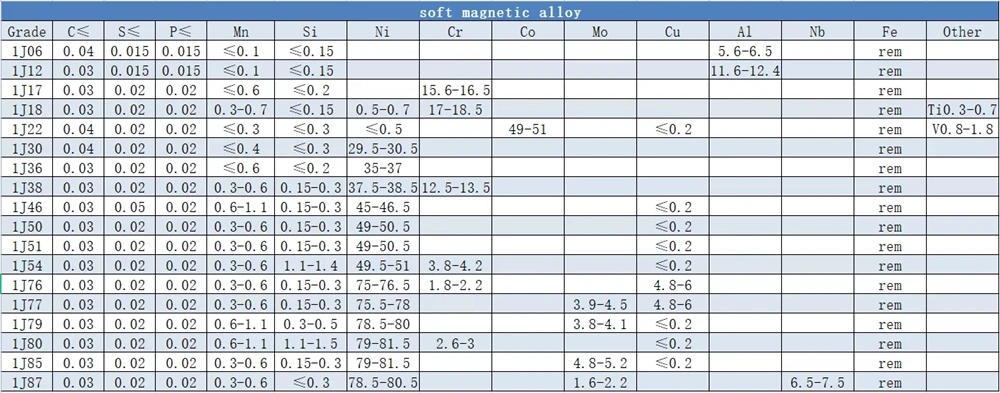

Soft magnetic alloys are a class of alloys with high permeability and low coercivity in weak magnetic fields. According to the different elements that make up the alloy, it can be divided into electromagnetic pure iron (industrial pure iron), iron-silicon alloy, iron-nickel alloy, iron-aluminum alloy, iron-silicon-aluminum alloy and iron-cobalt alloy, etc.1J06,1J12,1J17,1J18,1J22,1J30,1J36,1J38,1J46,1J50,1J51,1J54,1J76,1J77,1J79,1J80,1J85,1J87

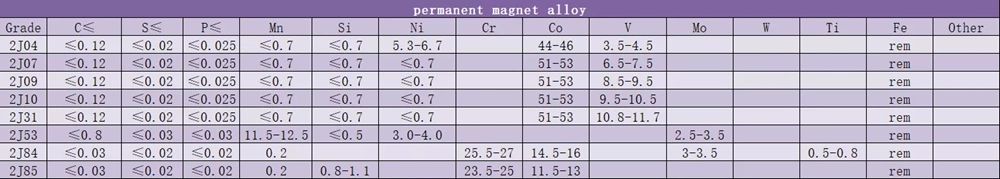

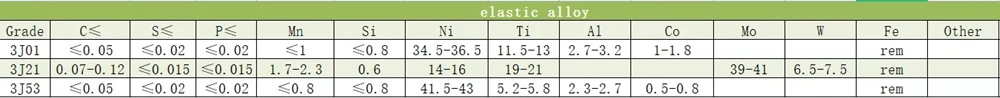

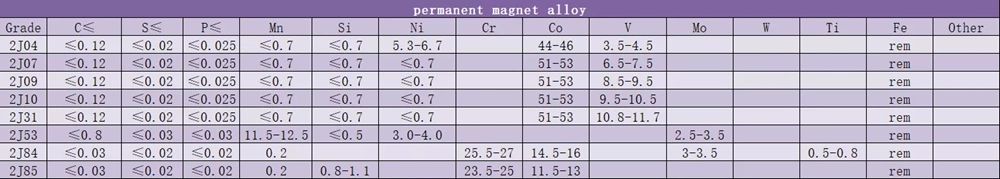

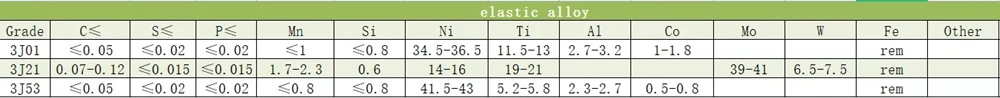

Permanent magnet alloy not only has high hardness and mechanical properties, but also has strong anti-demagnetization ability, high coercivity value (greater than 20kA/m), magnetic "hard" and other characteristics, so it is also called hard magnetic alloy.2J04,2J07,2J09,2J10,2J31,2J53,2J84,2J85 Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.3J01,3J21,3J53

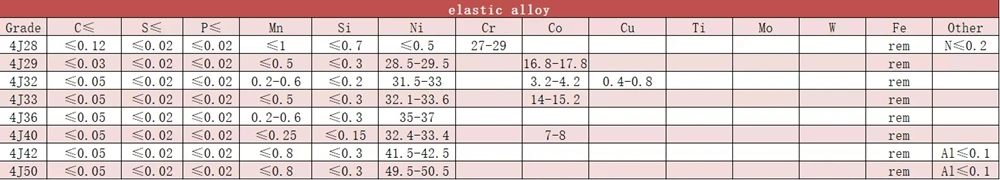

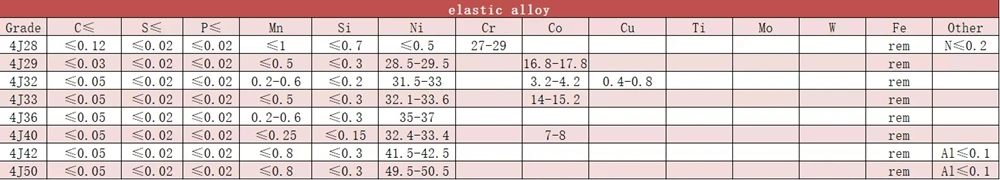

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.3J01,3J21,3J53 Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields.4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50

Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields.4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50

Precision alloys with nickel, chromium, aluminum and iron as the main components, the resistivity is about three times higher than that of manganese copper, and has a lower temperature coefficient of resistance and low thermal potential to copper, with good long-term resistance stability and resistance. Oxidation properties.

Precision alloys with nickel, chromium, aluminum and iron as the main components, the resistivity is about three times higher than that of manganese copper, and has a lower temperature coefficient of resistance and low thermal potential to copper, with good long-term resistance stability and resistance. Oxidation properties.

It is suitable for making precision resistance elements in various measuring instruments and meters, making precision micro-resistance elements and strain gauges.6J10,6J15,6J20,6J22,6J23,6J24

| expansion alloy | ||||||||||

| Grade | C≤ | S≤ | P≤ | Mn | Si | Ni | Cr | Cu | Al | Fe |

| 6J10 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.3 | ≤0.2 | nI+cO rem | 9-10 | ≤0.2 | ≤0.4 | |

| 6J15 | ≤0.05 | ≤0.02 | ≤0.03 | ≤1.5 | 0.4-1.3 | 55-61 | 15-18 | ≤0.3 | rem | |

| 6J20 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.7 | 0.4-1.3 | rem | 20-23 | ≤0.3 | ≥1.5 | |

| 6J22 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | rem | 19-21.5 | 2.7-3.2 | 2-3 | |

| 6J23 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | rem | 19-21.5 | 2-3 | 2.7-3.2 | |

| 6J24 | ≤0.04 | ≤0.01 | ≤0.01 | 1.0-3.0 | 0.9-1.5 | rem | 19-21.5 | 2.7-3.2 | ≤0.5 | |

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

What is your working time?

Monday-Friday : 8:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls e-mail us during our holiday if u have any questions.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 15 days after payment has been confirmed.

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments. Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields

Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields